Need help or advice? 52164-021

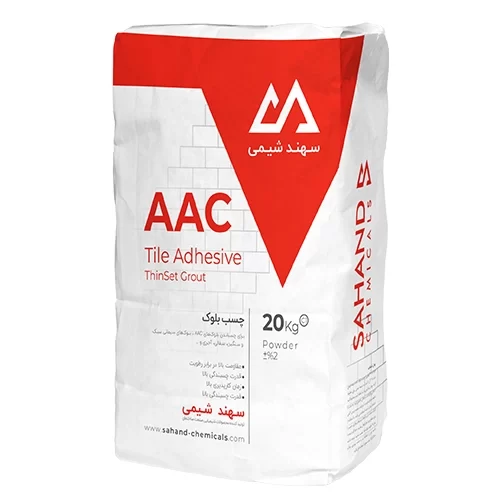

AAC block adhesive

Sahand Shimi AAC Block Adhesive is a cement and mineral-based product suitable for installing all types of autoclaved aerated concrete (AAC) blocks.

This product is a powder mixture that reduces the weight of the structure and levels the walls due to its speed of preparation, thin application, and high adhesive strength.

Sahand Shimi Block Adhesive is available in 20 kg bags.

3,600,000 ریال

Sahand Shimi Block Adhesive (Heplex Adhesive) is used for installing all types of autoclaved aerated concrete (AAC) blocks and lightweight blocks on interior and exterior walls of buildings. Sahand Shimi Block Adhesive is easy to prepare, quick to apply, has strong adhesion, and is highly durable.

Sahand Shimi is a manufacturer and sales center of various types of cement cleaners for tiles and ceramics of the highest quality.

To inquire about the price of block adhesive and purchase block adhesive, you can call 02152164 or contact our experts through the links on the contact us page.

AAC Block Adhesive vs. Cement Sand Mortar

Since lightweight and airy blocks are primarily designed and manufactured to lighten structures, the materials used to install them must also pursue this goal. The use of cement sand mortar increases the weight of the structure due to its high thickness during construction. In fact, these blocks are very less degradable than clay blocks and there is very little possibility of their being damaged during transportation. In contrast, Sahand Shimi Block Adhesive with its special formulation, in addition to providing double strength, also significantly reduces the weight of the structure due to its thin construction and also greatly increases the strength of the structure.

Applications of Sahand Shimi Block Adhesive

Sahand Shimi AAC Block Adhesive is a ready-to-use mortar that, after mixing it with water, can be used to glue the block and create a smooth surface on the interior or exterior of the structure. This product is used to install various types of autoclaved aerated concrete (AAC) blocks or lightweight blocks:

Sahand Shimi Block Adhesive (Sahand Shimi Heplex Adhesive) is prepared by adding only the appropriate amount of water, and due to the speed of preparation and application, it leads to great savings in cost and time.

The polymer additives in the formulation of Sahand Shimi Block Adhesive, in addition to the high adhesive strength it provides for connecting the blocks, have made this cement-based compound flexible. Due to the additives used in the manufacture of this product, it can be used in various environmental conditions.

Because of this feature, blocks installed with this cement-based powder adhesive will have acceptable resistance to structural stresses and building settlements.

It should also be said that this adhesive can be used to glue other lightweight blocks in addition to AAC blocks. This adhesive reduces the weight of the structure by about 75%, which greatly reduces the vulnerability of the structure.

Calculating the required amount of Sahand Shimi block adhesive

Each 20 kg bag of Sahand Shimi block adhesive typically covers a volume of about 1 cubic meter of block. This consumption depends on the method of application and the thickness of the block adhesive used.

How to prepare Sahand Shimi block adhesive

Mix each 20 kg bag of Sahand Shimi block adhesive with about 5 liters of water using an electric mixer (4 to 1 weight ratio). To do this, slowly add the powder to the water while stirring and continue mixing until a uniform and homogeneous mortar is achieved.

Then give the mortar a rest for 5 minutes and then mix again a little. Now your block adhesive is ready to use. This product is considered environmentally friendly due to its reduced water consumption and does not cause irreparable damage to the environment.

How to apply Sahand Shimi block adhesive

In the standard method, first apply a thin layer of adhesive to all sides of the block and install the block on the glued surface within a maximum of 20 minutes. One thing you should note is that before gluing the blocks together, clean the block surface from moisture, dust, and grease.

Application temperature and working time

The best working temperature for Sahand Shimi block adhesive is between +5 and +40 degrees Celsius. At lower temperatures, the drying time of the adhesive will be longer.

The period of use of powder tile adhesive after mixing with water (working time) depends on various factors such as temperature, volume of prepared adhesive, and its container.

In general, to create the best performance of block adhesive, it is recommended to prepare only the required amounts for a maximum of 1 hour and then proceed to make new adhesive.

Setting time

The setting time of block adhesive under standard conditions (temperature 25 degrees Celsius) is 72 hours, and the block adhesive reaches its maximum strength after 28 days. This period depends on various factors such as temperature, humidity, adhesive thickness and application conditions and may be less or more. Using AAC block adhesive can also be much easier and more resistant than using cement mortar.

Expiration date and storage conditions

Sahand Shimi block adhesive can be used for up to one year if stored in its packaging and in a dry place away from direct sunlight and moisture.

Reviews

There are no reviews yet.