joint garouts

Grout Powder

Sahand Chemical’s functional product used to fill joints between tiles and ceramics in indoor and outdoor environments and all vertical and horizontal surfaces.

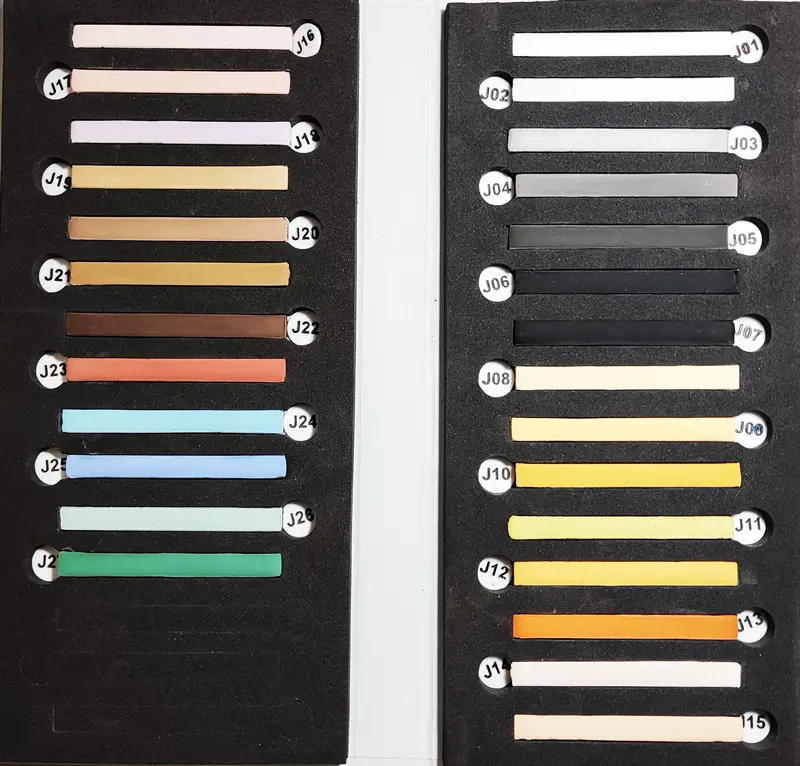

Sahand Chemical grout powder is a cement-based powder with polymer additives, available in 24 colors and with key features such as easy preparation and application, excellent adhesion, suitable flexibility, reduced shrinkage, water repellency, and color stability in various conditions. It plays a significant role in creating beauty, increasing the durability of tiles, and accelerating the work of tilers.

This product is available in 4 kg buckets.

7,000,000 ریال

This Sahand Chemical special grout powder is used for grouting tiles and ceramics on floors and walls of dry and wet environments such as rooms, halls, bathrooms, pools, etc. This product, with its fast application and easy preparation, also has high flexibility and durability and can be used for joints between tiles up to 6 mm wide and up to 10 mm deep.

This product can be used in indoor and outdoor spaces and for various types of granite stone, ordinary, glass, and pool tiles and ceramics. Other important features of this product include color variety and appearance stability, flexibility, and no shrinkage in the long term.

For more information about Sahand Chemical's various joint grout powders, Enter the following link.

Water Resistance

This Sahand Chemical product is a cement-based compound reinforced with polymer materials that has hydrophobic properties and significantly reduces water penetration.

However, joints made using traditional methods in constant contact with water in humid environments such as bathroom floors or interior pool surfaces did not have much resistance to water penetration. But Sahand Chemical’s hydrophobic joint grout powders, with their engineered and powerful formulation, prevent water penetration and moisture has no effect on their performance and durability.

To increase the water penetration resistance of this product, it is necessary to use Sahand Chemical mortar reinforcement resin (latex) instead of water to prepare the grout paste. The combination of these two products will waterproof the joints and prevent water from penetrating into them.

Grout Powder Applications

This product is an excellent option for the following applications:

- Special for grouting all types of granite stone, regular ceramic and tile, glass and pool tiles.

- Usable in outdoor, indoor, dry and wet environments.

- Usable in environments that are in constant contact with water (such as bathrooms, pools, saunas and jacuzzis).

- In environments that are exposed to thermal shocks (such as underfloor heating and cooling systems, saunas and jacuzzis).

- In these applications, it is necessary to replace part of the water with Sahand Chemical mortar reinforcement resin (latex) to prepare the grout powder.

This type of material has a high preparation and execution speed and saves a lot of money and tile work time.

In addition to creating hydrophobic properties, the polymer additives in the formulation of this Sahand Chemical product reduce its shrinkage after drying and increase the adhesion, flexibility and resistance of tile joints against thermal shocks.

Application of Grout Powders for Facades

Facade brick joints are usually wider than tile joints. Considering that this product can be applied to joints with a maximum width of 6 mm, it cannot be used for facade joints that are often wider than this.

It should be noted that using Sahand Chemical grout powder for joints wider than 6 mm will cause it to crack.

Outdoor Use

This product is used for grouting inside buildings in the usual way and in combination with water.

But for outdoor use, it is better to use Sahand Chemical mortar reinforcement resin (latex) instead of part of the water consumed to mix with grout powders.

Adding this polymer resin to the combination of grout powders greatly increases its adhesion, flexibility, water resistance and ability to withstand various weather conditions and will have a significant effect on the performance and stability of the joints.

Use in Sauna and Jacuzzi

The walls and floors of saunas and jacuzzis are intermittently exposed to thermal shocks and frequent temperature changes. In these environments, it is necessary to use Sahand Chemical mortar reinforcement resin (latex) instead of part of the water consumed to mix with this product.

Adding this polymer resin to the grout powders greatly increases their adhesion, flexibility and water resistance and prevents separation due to thermal stresses.

Grout Powder Combinations with Other Products Based on Application

| Application Areas | Grout Powder | Mortar Reinforcement Resin (Latex) |

|---|---|---|

| Indoor Grouting | ⚫ | |

| Outdoor Grouting | ⚫ | ⚫ |

| Grouting in Saunas and Jacuzzis | ⚫ | ⚫ |

Calculating the Required Amount

The consumption amount of Sahand Chemical grout powder depends heavily on the total work area, joint width, joint depth, and tile dimensions. The amount of grout powder is calculated using the following formula:

(Tile Length * Tile Width) / ((Tile Length + Tile Width) * Joint Width * Joint Depth * 1.56) = Consumption rate per square meter (kg/m²)

By substituting the tile and joint dimensions into the above formula, the numbers can be used in the following table:

Grout powder consumption per square meter (kg)

| Grout line width (mm) | Dimensions of tile (cm) | |||||

|---|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | Tile width | Tile length |

| 3/9 | 3/12 | 2/34 | 1/56 | 0/78 | 2 | 2 |

| 1/05 | 0/84 | 0/63 | 0/42 | 0/12 | 15 | 15 |

| 1/4 | 1/12 | 0/84 | 0/56 | 0/28 | 20 | 20 |

| 0/5 | 0/4 | 0/3 | 0/2 | 0/1 | 30 | 30 |

| 0/35 | 0/28 | 0/21 | 0/14 | 0/07 | 60 | 30 |

| 0/35 | 0/28 | 0/21 | 0/14 | 0/07 | 90 | 30 |

| 0/4 | 0/32 | 0/24 | 0/16 | 0/08 | 40 | 40 |

| 0/3 | 0/24 | 0/18 | 0/12 | 0/06 | 60 | 60 |

| 0/3 | 0/24 | 0/18 | 0/12 | 0/06 | 80 | 80 |

| 0/3 | 0/24 | 0/18 | 0/12 | 0/06 | 120 | 60 |

| 0/2 | 0/16 | 0/23 | 0/08 | 0/04 | 240 | 120 |

Preparation Method

Mix each 4 kg bucket of Sahand Chemical grout powder with about 1.5 liters of water using an electric mixer at low speed (3 to 1 weight ratio).

To do this, pour water into a container with a suitable capacity and slowly add the powder to the water while stirring.

Continue mixing until a uniform and homogeneous mortar is obtained. Then let it rest for 5 minutes and then mix it again a little. Now the grout powder is ready to use.

Substrate Surface Conditions

It is recommended that the joints and spaces between the tiles where the grout powder is applied are free of any contamination, dust, paint and grease. The presence of contamination on the surface of the joints prevents the grout powder from adhering to it and the separation of the grout paste from the surface.

How to Apply Grout Powder

The prepared grout paste is applied to the joints using a grout trowel. The surface of the tiles around the joints must be cleaned with a damp cloth or grout sponge after the initial setting and before the grout powder is completely dry. If traces of grout powder remain on the surface of the tiles and surfaces that are not sensitive to acid, use Sahand Chemical cement cleaner spray to clean them.

Operating Temperature and Workability Time

The best operating temperature for this Sahand Chemical product is between 5 and 40 degrees Celsius. At lower temperatures, the drying time of the grout paste will be longer.

The shelf life of this product after mixing with water (workability time) depends on various factors such as ambient temperature and the volume of prepared powder. In general, to create the best performance of grout powder, we suggest preparing only the amounts needed for grouting up to a maximum of 30 minutes and then proceed to make new mortar.

Setting Time

The initial setting time of grout powder under standard conditions (temperature 25 degrees Celsius) is 24 hours and finally reaches its maximum strength after 28 days. This time depends on various factors such as temperature, humidity, joint depth and execution conditions and may be shorter or longer.

Expiration Date and Storage Conditions

Sahand Chemical grout powder can be used for up to one year if stored in its packaging and in a dry place away from moisture.

.

2 reviews for joint garouts

There are no reviews yet.